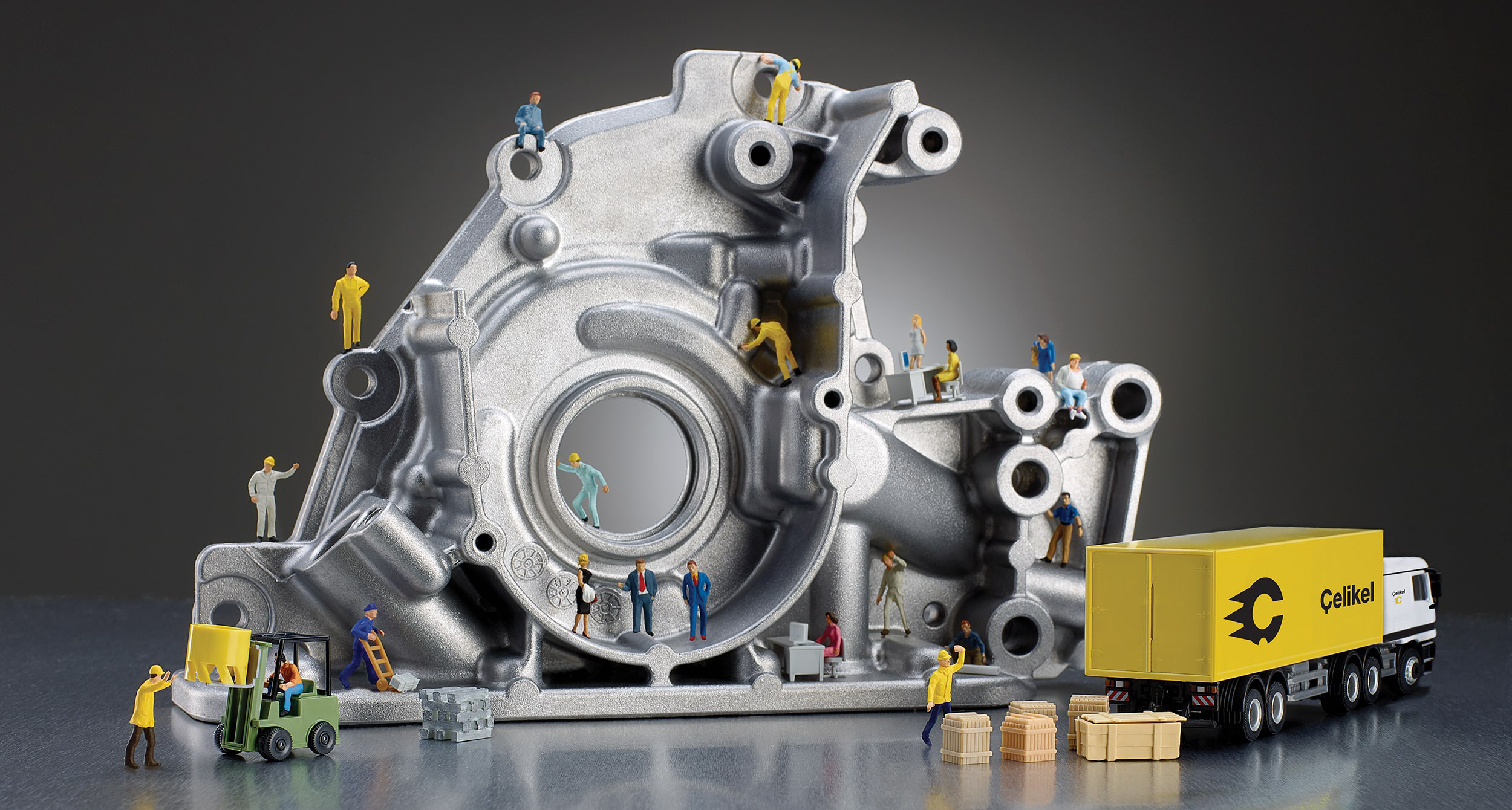

Production & Technology

Non-Stop Production

Çelikel has been increasing its market share day to day and is proud to be selected as the strategic supplier by the leading companies operating in the automotive industry as well as being awarded for quality, logistics, competitiveness and sustainability categories. Çelikel’s production is 100% dedicated to automotive industry.

Our wide machinery park has been built to contain back-up machines for each process and control division in order to provide continuous production of 24 hours in 3 shifts. Today, the knowledge and the experience gained over the years have transformed into a proactive business approach to which Çelikel’s strategy and investments are made accordingly.

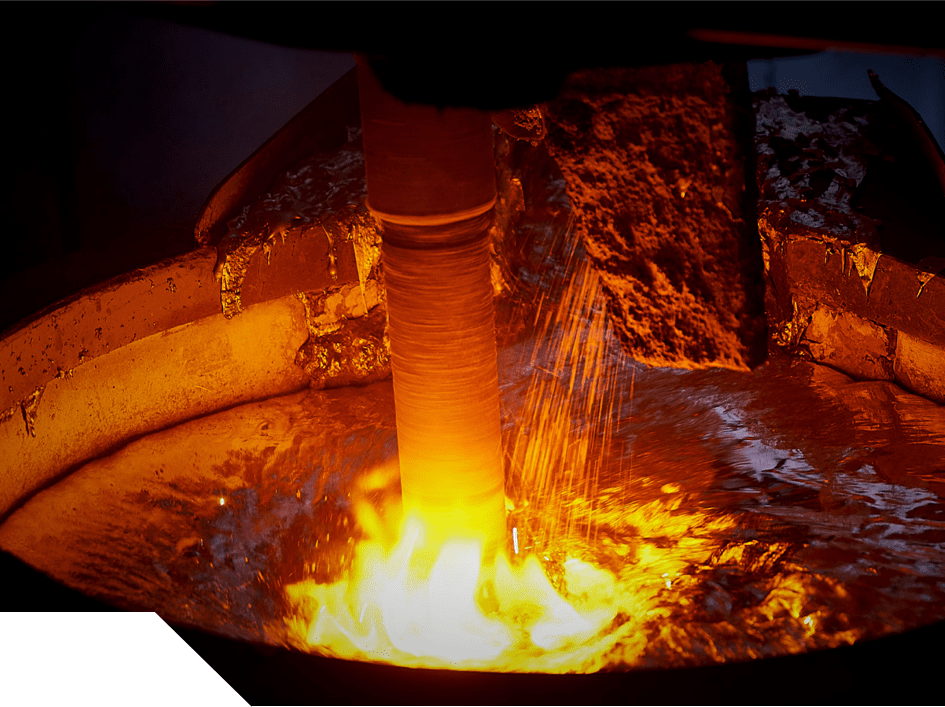

Melting

The melting zone is designed to allow six different alloy types to be processed simultaneously with a total melting capacity of 240 tons per day prior to the High Pressure Die Casting process.

The whole process takes place via using state-of-the-art manufacturing facilities and upscale machinery such as shaft melting furnaces, rotary degassing units, density index measurements that are integrated with ERP traceability system.

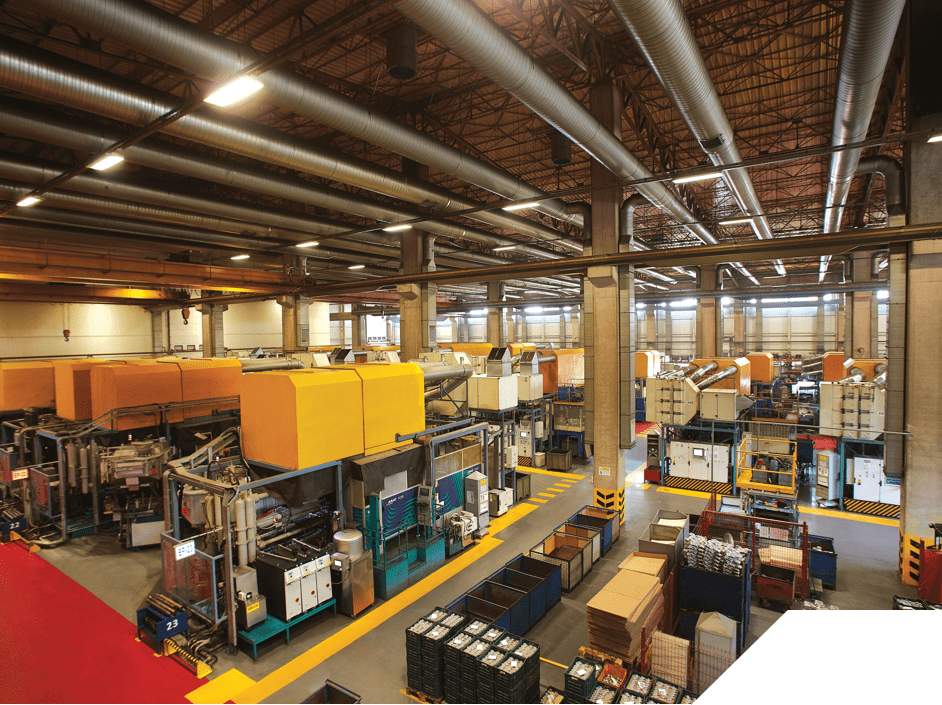

Casting & Foundry

With 22 high-end HPDC machines from 550T-2200T clamping capacity and an average age of 4, Çelikel can produce parts from 500 grams to 15 kilograms rapidly and flawlessly for its customers. More than 60% of the casting machines are cell type and fully automated.

Çelikel’s production plant, ensuring high quality and traceability, can provide the required high durability for HPDC parts based on customer requirements and specifications using its T5 & T7 heat treatment furnaces.

State of Art Auxiliaries:

Cell-type 6 axis robotic spraying

and extraction units

Porous Plug Dosing Furnaces

Jet Coolers

High Vacuum Equipments

Integrated thermoregulation

devices with DCM

Squeeze Pin Units

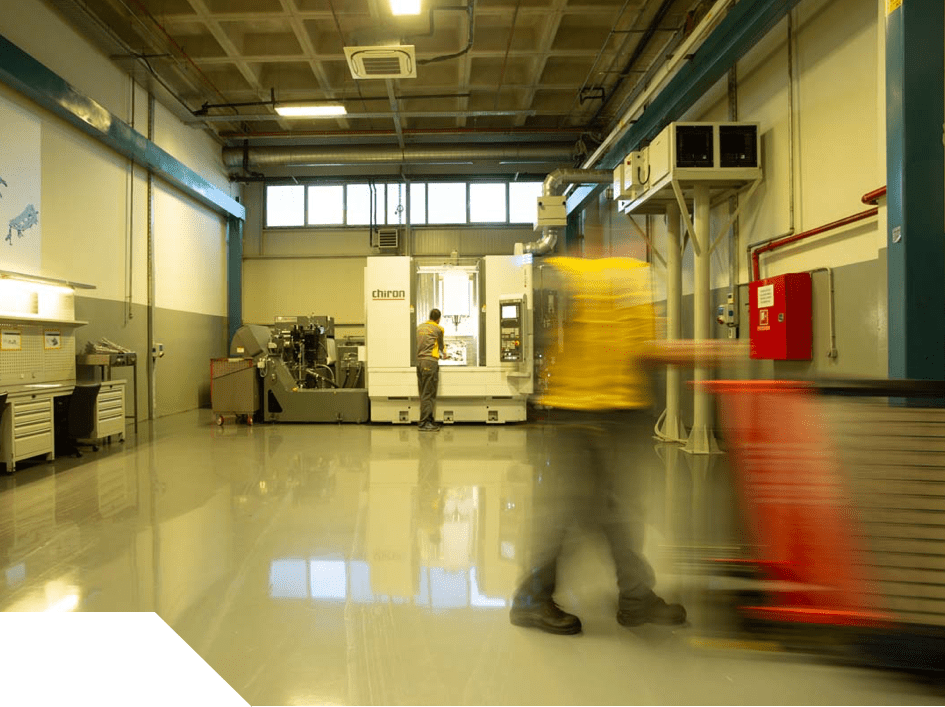

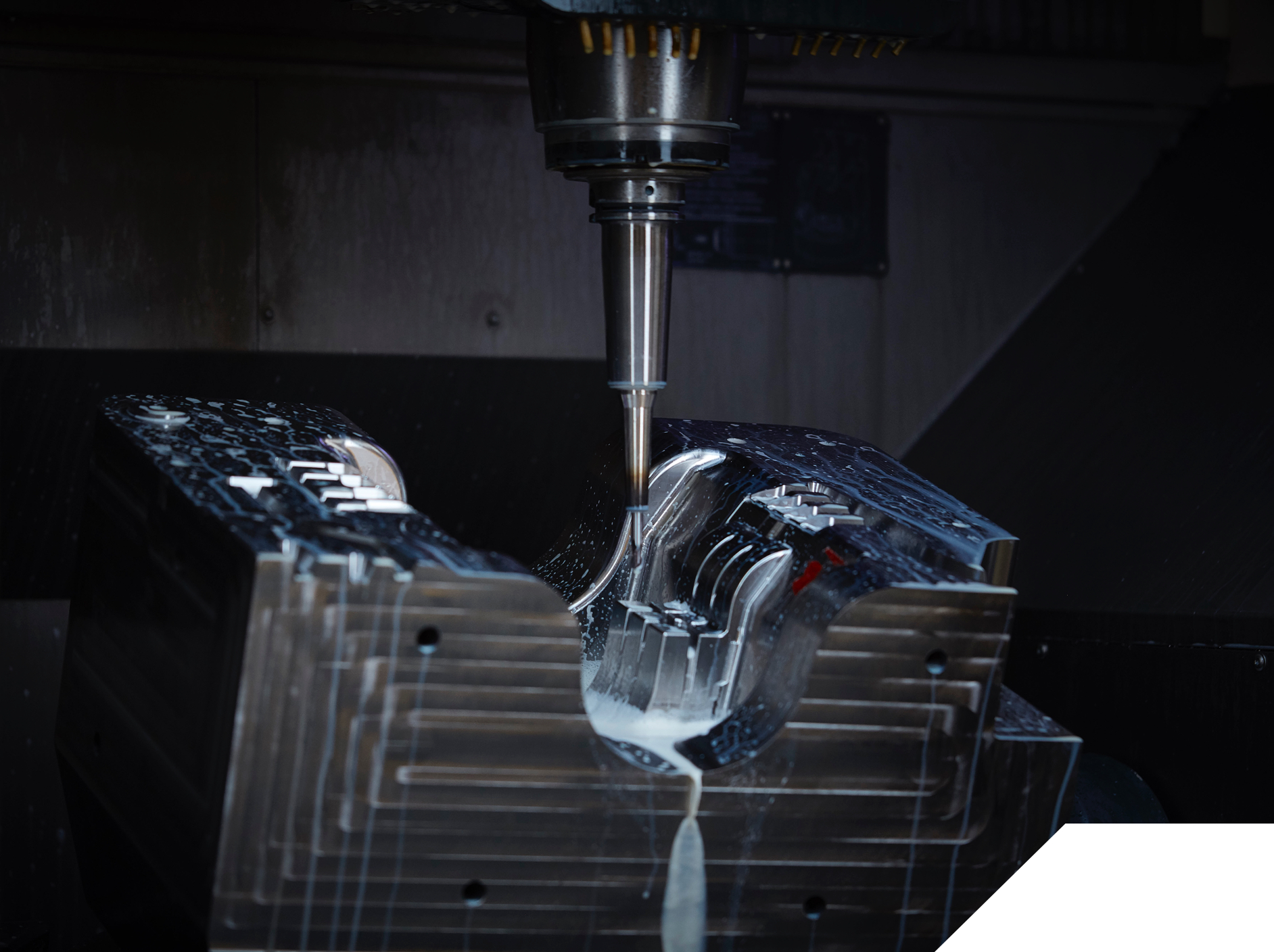

Machining

Çelikel’s machine park, which is composed of high technology equipment and based on lean manufacturing principles, has high efficiency values. Our high-tech double pallet machines are specially designed for the high pressure aluminium die cast parts with high machining and tool changing speeds, which ensure that they obtain tight tolerances at a micron level with precise dimension and quality.

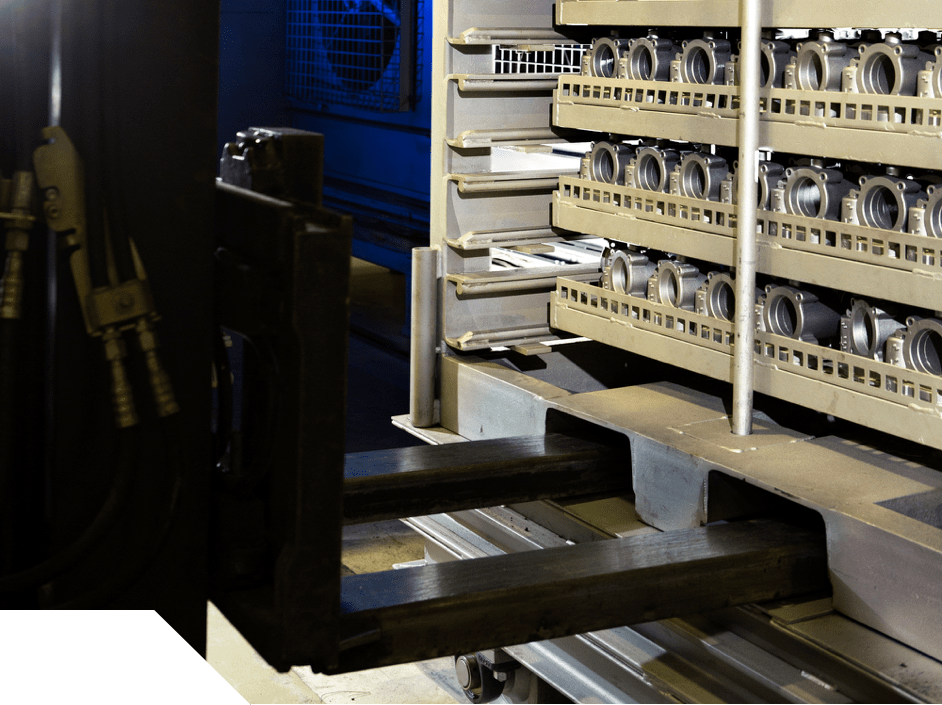

CNC Machine Park features:

21x Chiron Vertical Machining Centers

2x SW Horizontal Machining Centers

Smart Machining Tool Cabinet

Mapal Uniset-V Vertical Tool Presetter

Fully Automated Assembly Line

More than 50% of the machining centers are cell type and fully automated.

Assembly

Considering customer needs, assembly operations are performed with custom designed automatic state-of-the-art machines. In order to produce long lasting leak free parts, friction stir welding (FSW) is also applicable on our gemba.

Auxiliary Processes

Additional processes are applied on the components regarding the customer needs and specifications, such as:

– Heat Treatment (T5 & T7)

– Washing (Tunnel & Basket Type)

– Camera Control

– Shot Blasting & Vibration

– Cleanliness Testing

– Leakage Testing

– Mechanicals Testing (Compression, Tensile, Bending)

– Poka-Yoke Based Gauges & Equipments

Maintenance

Çelikel’s regularly trained and highly qualified technical personnel is ready 24/7 to perform maintenance applications on the machines and moulds by following the performance analysis with ERP system to prevent production disruption.